Product Spotlight: Building an accessible vertical farm

What does it take to make a modular vertical farm wheelchair accessible?

Vertical farms can be narrow spaces with many hard to reach corners making it difficult for those with mobility needs to be an operator.

Even the premise of vertical farming - growing more using less space - doesn’t lend itself to thinking of it as a spacious or an accessible work environment.

Why does this matter? Local food is better when it’s accessible to all - from those who get to eat it to those who get to grow it.

Current vertical farming technology is often narrow, tall, and can be a challenge to navigate, but industry modifications can unlock employment opportunities for operators living with disabilities and help make vertical farming more accessible to all.

The first wheelchair accessible vertical farm in Canada

Growcer partnered with the Reena Foundation and the Rick Hansen Foundation to develop the first accessible modular vertical farm in Canada.

The farm allows you to locally grow 5,600+ pounds of fresh, nutritious produce all year round.

What makes an accessible vertical farm different?

Let’s think about what a regular modular farm looks like:

Stacked growing rafts piled high to the ceiling

Narrow working aisles between runways

No room to turnaround if you’re using a wheelchair

Manual doors

Light switches and sensors are all at eye level for someone standing

When creating an accessible farm, we had to think of ways to overcome these barriers so an operator using a wheelchair would be able to grow inside the vertical farm.

“We worked with a consultant recommended by the Rick Hansen Foundation to certify the project and they helped guide us on how someone using a wheelchair would need to operate the farm,” says Adam Fry, Growcer’s product manager leading the project. “It was interesting to see how small details make a difference when designing a more accessible farm.”

Accessibility upgrades

After a consultation process, several modifications were implemented:

Adding an automated sliding door to replace the plastic curtain to the grow room.

This update not only enhances accessibility but also plant health because it creates an impenetrable barrier to pests.

An automatic sliding door sits between the mechanical room and grow room.

In an Osiris farm, a plastic curtain acts as an additional barrier between the mechanical room and grow room.

Creating turnaround zones at the front and back of the farm.

Without turnaround zones, someone using a wheelchair would be forced to “reverse” themselves out of the farm and only ever do farm tasks facing one way. Plus, the restriction becomes a safety concern when it comes to exiting the farm. With turnaround zones, a person using a wheelchair or mobility device has enough space to turn around at the front and back of the farm.

In the Osiris Access farm, there are turnaround spaces at both ends of the farm.

The minimum turning space required to perform a complete 360-degree turn is 1,700mm diameter, and this was built into the back of the farm to create a turnaround zone.

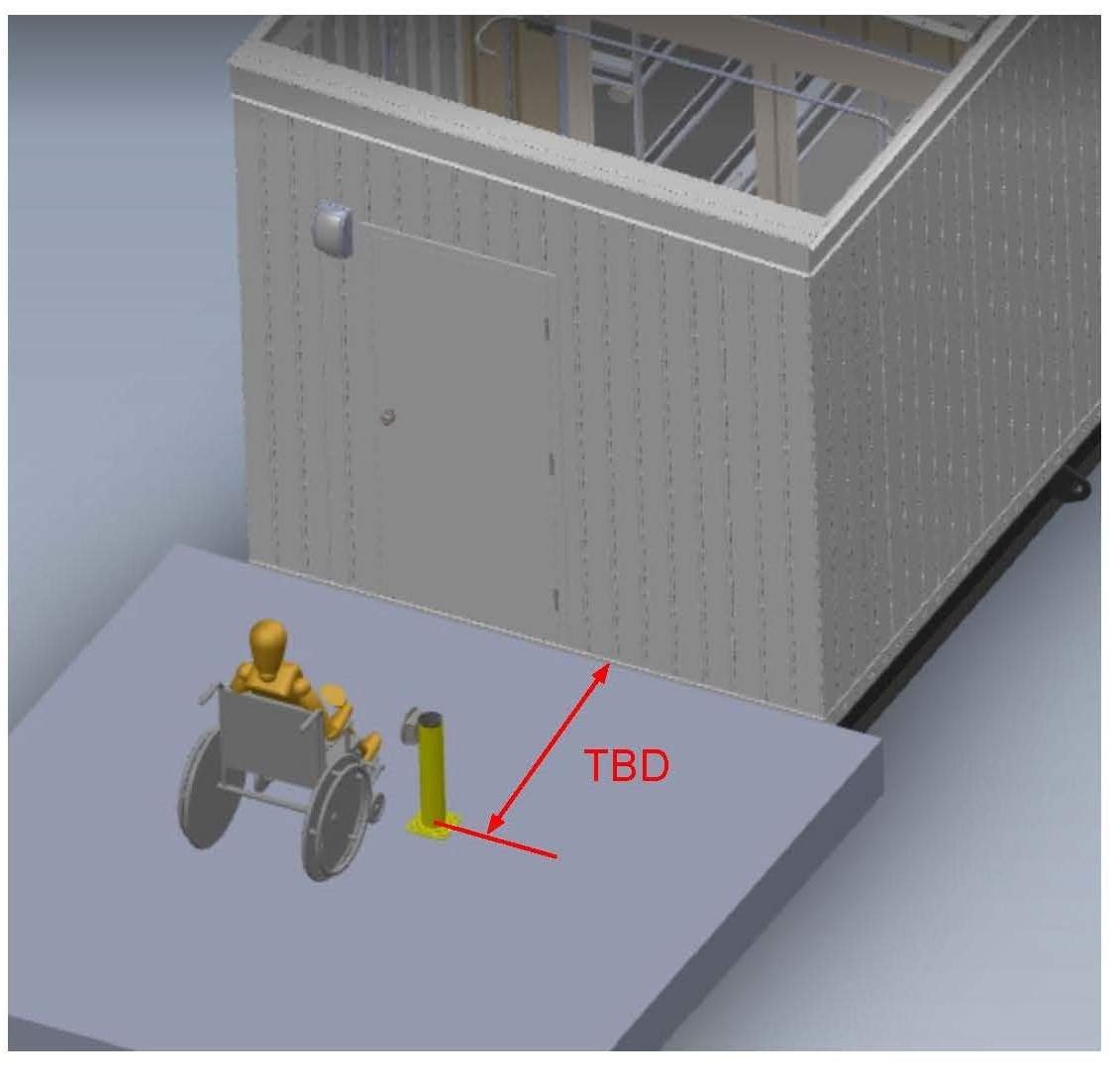

Automating entry doors and ensuring the farm is ramp accessible.

The same concept applies for buildings with automated doors that open with a push of a button - except this time the automated door is on the farm.

One of the earlier brainstorming drawings when deciding how to add an automatic entry way.

Designing a fold out work table at the back of the farm to add more workspace without compromising the turnaround area.

In Growcer’s regular Osiris farm, the workbench sits on top of the seedling area in the front of the farm, limiting how much space is available to turn around and restricting the workbench to an inaccessible height.

By designing a foldout work table that stows away when not in use, it allows an operator to have space to turn around or use the table to work when needed.

Growcer also relocated the seedling area to the back of the farm and shortened one of the growing racks to increase the space upfront. Moving the seedling area allowed the farm to have a turnaround zone at the front of the farm, and with the foldout work table on the other end, also maintain a turnaround zone at the back of the farm too.

The foldout work table at the back of the Osiris Access farm.

In an Osiris farm, the seedling area sits at the front and there is no room in the back or front to turn around if you’re using a mobility device.

Widening working aisles and lowering table and switch heights.

In one of Growcer’s very first farms, the working aisle width was approximately 30 inches (30”) or 2.5 feet (2.5’), which is a tight space for anyone let alone an operator trying to harvest plants. To better the grower experience, all of Growcer’s Osiris farms have wider working aisles (51” or 4.25’) for easier operations.

Put simply, the wider aisles ensure there’s enough space for a wheelchair to comfortably fit and lower table and switch heights make it easy for anyone to reach.

The Osiris farms have a wider working aisle making it easier for operators.

An example of the aisle width in one of Growcer’s first farms.

The modifications resulted in a 33% reduction in growing area because of the turnaround areas and need for more working space.

When it comes to designing more accessible technology, sometimes there are tradeoffs. To add more working space, growing space had to be sacrificed. Thankfully, all the modifications only resulted in a 33% reduction so the farm can still produce more than 5,600 pounds of fresh produce each year.

Featured Farm: GReena

The GReena farm finally landing on site.

Reena is a non-profit in Vaughan, Ontario providing support for individuals with developmental disabilities within a framework of Jewish culture and values.

Reena ambitiously started the process to achieve Kosher certification to sell culturally relevant produce while employing nonprofit members in its accessible modular farm.

“The really exciting part here is the experiment that we’ve been working on together with Growcer and the kosher certifying authority here in Toronto,” begins Fred Winegust, stakeholder relations with Reena.

“For a long time, one of the biggest problems was bug infestations in hydroponically grown leafy greens. Working together with a set of rabbis and with Growcer, we reengineered the interior. We also made sure that for the first time it is also wheelchair accessible.”

“So our goal over time is to look at this and potentially cookie cutter it to other developmental services organizations across the province, as well as other communities who observe the kosher laws and show them how it can be done,” Winegust says.

Vertical farming for all

Growcer’s mission is to make year-round farming more accessible for all, so we like the more accessible option whether it’s our hydroponic set up or accessible farm.

We pair our tech with a full suite of services to get you growing year-round and keep you growing, from helping with installation to plant health training to produce distribution. To learn more about how you can start growing, start a conversation with a member of our team today at growcer.ca/contact.

Download the Osiris Access Brochure and Spec Sheet

hbspt.forms.create({region: "na1",portalId: "3059315",formId: "560f6473-7c12-43c1-90fa-8193c24f57ce"});